|

| September 07, 2021 | Volume 17 Issue 33 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Neat: 3D-printed copper windings for electric motors

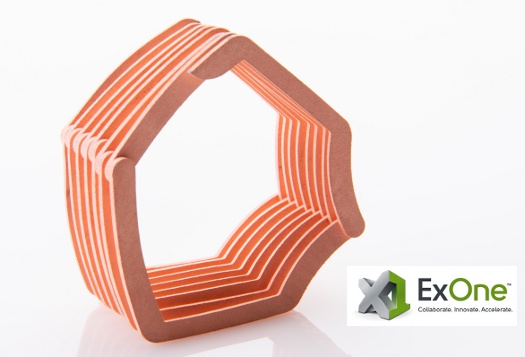

3D-printing experts ExOne and startup Maxxwell Motors have successfully proved out a new concept for 3D printing a high-efficiency copper e-winding design for electric motors using a binder jet system. The new process eliminates many of the challenges that come with traditional manufacturing of copper coils for electric motors.

Additional development and testing of Maxxwell Motors' 3D-printed copper winding is now underway. [Credit: Maxxwell Motors/ExOne]

ExOne (North Huntingdon, PA) is a global leader in producing industrial sand and metal 3D printers using binder jetting technology. In binder jetting, machines bond layers of metal powder together with a binding agent before final sintering in a furnace. The technology excels at making complex metal parts with excellent mechanical properties.

Maxxwell Motors is a new Tennessee-based venture focused on improving how electric motors are designed and manufactured, specifically axial flux electric motors that do not use rare-earth materials. These motors can be used in electric cars as well as a range of other heavy-duty vehicles and industrial devices. Maxxwell holds nine U.S and global patents and has launched two products so far: a 10-kW air-cooled motor generator and a 150-kW liquid-cooled motor.

Maxxwell is led by an interesting team. Chairman Gary Wells is the former CEO and current board member of Wells' Dairy, the maker of Blue Bunny and other ice cream brands. CEO Michael Paritee is a former General Motors executive who managed several advanced vehicle programs and has guided technology firms for more than a decade.

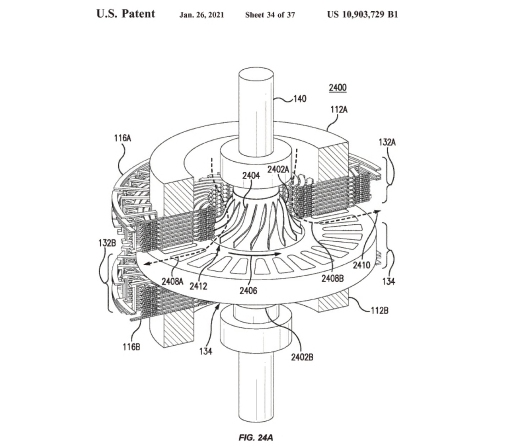

Optimized copper windings and rotors in electric motors are among the factors enabling the automotive industry's transition to hybrid and pure electric power vehicles. However, current methods of manufacturing the windings are costly, inefficient, and limit designs in a way that also limits their performance.

In one of Maxxwell Motor's patented electric motor designs, the copper coils for the stator winding fully surround the motor to conduct electricity and can be seen in the areas marked 132A and 132B. Approximately 36 coils are used in a standard motor design in each of those areas, but Maxxwell and ExOne aim to consolidate all the coils into a single 3D-printed part, saving time and money. [Credit: Maxxwell Motors/ExOne]

"When we 3D print it [the motor winding], a lot of the challenges just go away, and we can actually improve the performance of the motor itself," Paritee said. "At Maxxwell, we're taking the most sustainable, and additive manufacturing, point of view as possible to truly improve efficiency, reduce waste, and optimize performance."

Ultimately, Maxxwell's goal is to 3D print each winding assembly as a monolithic piece, eliminating the need for coil wrapping, bending, tooling, and welding of individual parts together.

VIDEO: What is metal binder jetting? [Credit: ExOne]

When produced with binder jet 3D printing, the final part would require fewer manufacturing steps, provide a means to better energy utilization, and produce less material waste, also resulting in components that are more efficient and deliver improved performance. What's more, high-speed binder jetting is relatively affordable.

Learn more about ExOne printers and capabilities at exone.com/en-US.

Learn more about Maxxwell Motors at maxxaf.com.

Source: ExOne

Published September 2021

Rate this article

View our terms of use and privacy policy